Complex Builds. Done Right.

Scalar Performance has always been about pushing boundaries. Starting with the SCR1 — the first all-electric club race car sanctioned to compete against combustion — we proved that high-tech builds can be made to work under real racing conditions. Since then, we’ve applied that same motorsport-driven approach to projects ranging from hybrids and off-road vehicles to heavy-duty trucks and even undercover prototypes. Today, we don’t offer a menu of services — we choose projects that are ambitious, complex, and worth doing right. When a build requires deep integration of electrical, mechanical, and software systems, that’s where we thrive.

Complex Powertrains

From the SCR1 all-electric race car to hybrid experiments and one-off builds, Scalar has always been about making ambitious powertrains work in the real world. We know what it takes to package batteries, motors, inverters, and supporting systems into a chassis that was never designed for them — and then push them to the limit.

That expertise extends to modern crate motors, where “plug and play” rarely works as advertised. We’ve integrated OEM and aftermarket powertrains into platforms from completely different manufacturers, solving the mismatches in controls, packaging, and calibration that make most builders give up.

We don’t just swap components; we engineer complete solutions. Whether the project is an experimental drivetrain, a high-performance EV, or a hybrid with multiple power sources, our focus is on making sure it delivers performance and reliability, not just bench specs.

Systems Integration

Complex builds succeed or fail on integration. Wiring, sensors, actuators, controls — each subsystem might work in isolation, but bringing them together is where most projects break down.

What's Included:

Integration of non-OE powertrains and systems into existing vehicle platforms.

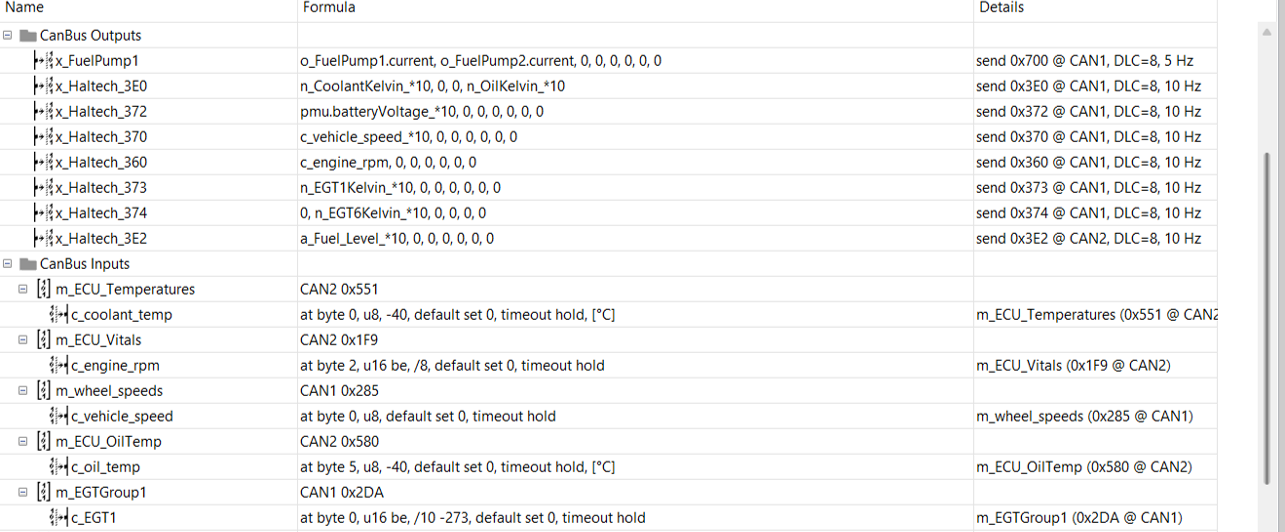

Expertise in CAN bus reversing for seamless communication between components.

Harness integration to ensure proper connectivity and functionality.

Computer network integration to maximize performance and efficiency.

We specialize in system architecture and harness development as part of larger builds, ensuring that every component communicates properly, every signal is reliable, and the whole vehicle works as a single unit. Our approach comes from years in motorsport, where a small integration failure can end a race.

Calibration and Controls

A vehicle that “runs” isn’t the same as one that’s dialed in. Calibration is where the difference shows up — in drivability, performance, and reliability. From EV motor tuning to hybrid power blending and torque control, Scalar brings deep experience in making vehicles behave the way they should.

We’ve tuned in the harshest environments — road racing, endurance events, and performance testing — where safety and reliability matter as much as speed. Our calibration work doesn’t just solve problems; it unlocks the potential of the hardware.

Prototyping and Development

While we love starting with a 3D scan and building in CAD, eventually ideas need to leave the computer screen and become something real. With in-house rapid prototyping tools — including CNC plasma and large-format multi-tool 3D printing — we can move from concept to part in hours instead of weeks.

And sometimes the fastest path isn’t high-tech at all. We’re not afraid to drop the software and go old-school CAD: Cardboard Aided Design. The process always matches the challenge — whether that means a digital model or scissors and tape.

This flexibility lets us test, iterate, and refine quickly, whether it’s a one-off bracket, a cooling duct, or a proof-of-concept assembly. Prototyping isn’t the end goal; it’s the bridge that keeps ambitious projects moving forward when off-the-shelf parts don’t exist.

Interface and Dash Design

The driver only sees what the dash shows them — and in complex builds, that data can make or break the experience. Scalar has developed custom dashboards and driver interfaces that put critical information front and center, without clutter or noise.

We focus on motorsport-grade reliability and clarity. From CAN-driven displays to fully custom interfaces, our goal is to give drivers and builders the visibility they need to trust the vehicle, push it harder, and understand what’s happening under the skin.

Electronics & CAN Bus

Modern vehicles live on networks. If you can’t speak CAN, you’re blind. Scalar has spent years reverse-engineering OEM CAN bus messages, designing custom control strategies, and making aftermarket systems play nicely with factory electronics.

We’re especially fluent with ECUMaster platforms, but our approach applies to any project: sniff, decode, validate, and integrate. Whether it’s enabling a new feature, bypassing a factory module, or creating a complete controls package, our CAN expertise is often what makes the impossible build actually possible.